Restaurant Inventory Management Flow

User documentation

07/15/2025

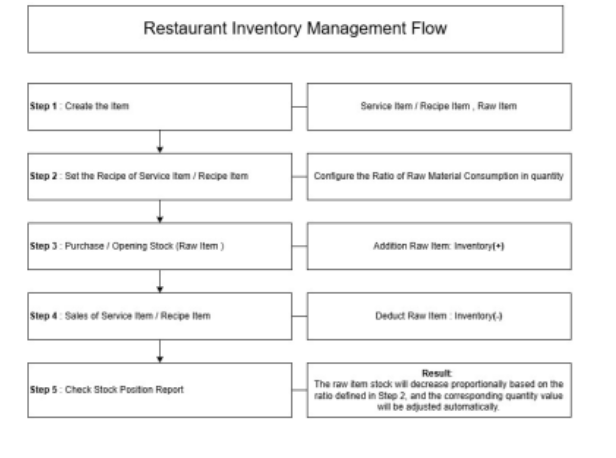

Restaurant Inventory Management Flow¶

The restaurant inventory management flow outlines the systematic process of handling raw materials, recipe items, stock updates, and sales transactions. It ensures efficient tracking of inventory, from procurement of raw ingredients to the sale of finished products, maintaining accurate stock levels and minimizing waste.

Inventory System Flow

In this process, the initial step involves creating both the service/recipe items (finished products ordered by clients, such as Momos and Chowmein) and the raw items (materials like onion, keema, maida, etc. used to produce the recipe item). Next, the quantity of raw materials required to produce the recipe item is configured in the recipe settings.

After this setup, the client must either purchase the raw materials or enter the opening stock of raw materials, which will add inventory to the system. Once the inventory is added, the restaurant can sell the finished goods listed in the menu. Upon saving the sales bill, the stock of raw materials linked to the recipe item will automatically decrease based on the sale of finished goods or service items.

Additionally, the stock position can be monitored through the inventory reports for better tracking and management.

Steps for Managing Recipe-Based Inventory

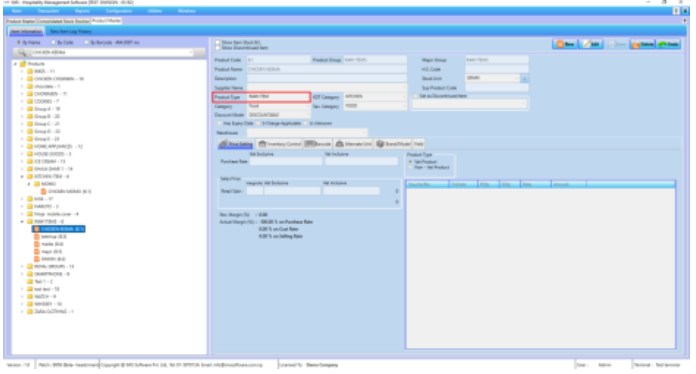

Step 1: Generate the Service or Recipe Item

• Create the desired recipe item (e.g., Chicken Momo) using raw materials (e.g., minced chicken, masala, wheat, etc.).

Figure 1: Creating raw items

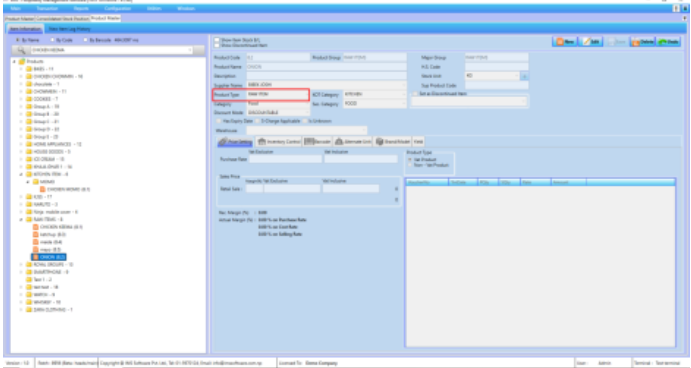

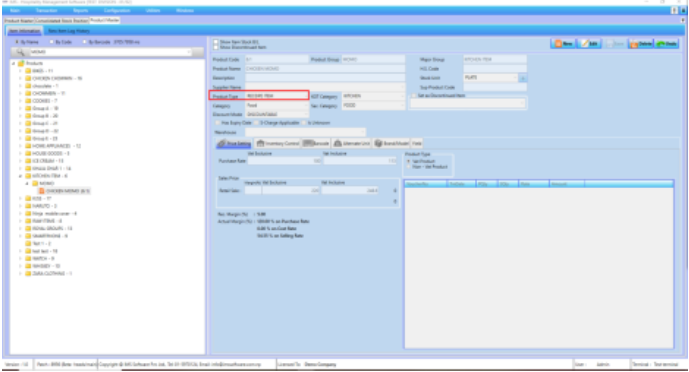

• Navigate to Configuration > Product Master to define the recipe item in the product master list.

Figure 2: Creating Recipe Item

Step 2: Define the Recipe Consumption

• Post the recipe under Utility > Recipe Setting to specify the quantity of raw materials consumed during the production of the recipe item (e.g., Chicken Momo).

Figure 3: Defining the Recipe Consumption

Step 3: Stock Up Raw Materials

• Record the purchase of raw materials through the Purchase Invoice, which will automatically increase the stock of items like minced chicken and onions.

Figure 4: Purchasing the raw items

Step 4: Sell the Recipe Item

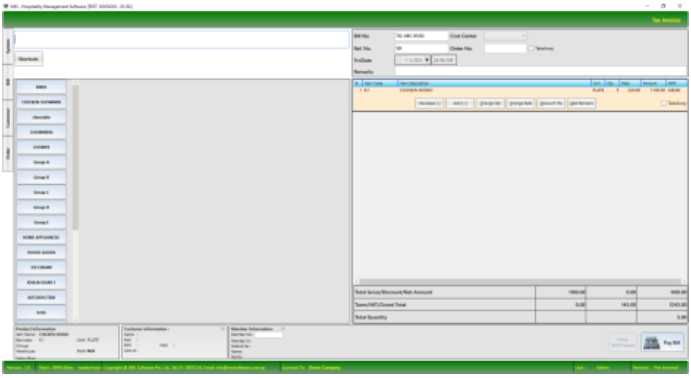

• Generate the sales invoice for the recipe item (e.g., 5 Plate Chicken Momo) through IMS POS.

Figure 5: Selling the Recipe Item

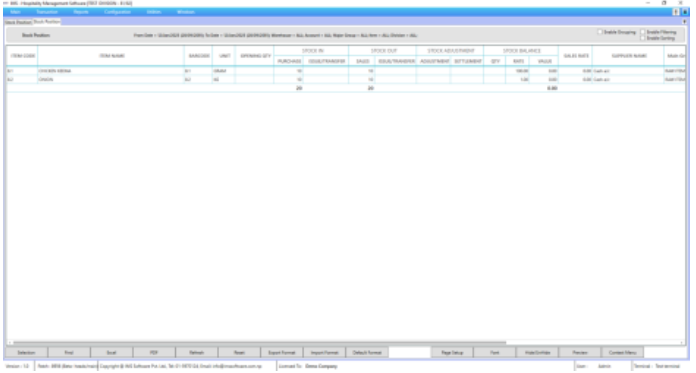

• After saving the sales invoice, the stock of the associated raw materials should decrease automatically.

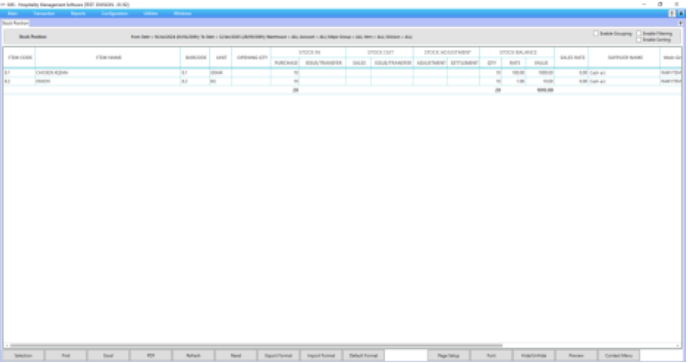

• To verify stock changes, go to Reports > Inventory Report > Stock Position.

Figure 6: Before Selling Recipe Item

Figure 7: After Selling Recipe Item